Transforming Cacao from bean to disc

Transforming raw cacao beans into ceremonial cacao discs is a many step process, throughout which care must be taken to preserve the cacao’s energetic integrity.

STEP 1 ROASTING:

The first step is roasting the cacao beans, which activates them, brings out their flavor, and dries out the remaining moisture.

For ceremonial cacao we use only the minimal heat needed to bring out the natural flavors in our premium cacao. In contrast, much industrial cacao is processed with high heat, to achieve uniformity and mask off flavors from low quality inputs.

Cacao does quite well with heat. We lightly roast our cacao to mirror the wisdom of indigenous cacao practices we encountered that always toast cacao to bring the alchemy of the fire element into the chocolate making process.

STEP 2: CREATING NIBS

Next, the roasted cacao beans are mechanically cracked to break them into small pieces of shell and bean. A multi-layered screen is used to sort these cracked cacao beans into groups based on the size of fragments.

Then, the broken pieces of shell and bean are winnowed using a strong air current, which removes the lightweight inedible shell from the heavy pieces of cacao beans.

This process results in cacao nibs, which are then ground in several stages.

STEP 3: GRINDING

The grinding process liberates the cacao butter naturally present in cacao nibs. Cacao butter is liquid at body temperature, so just low heat with prolonged mechanical grinding over the course of a day will transform the nibs into completely smooth 100% cacao with an average particle size of about 20 microns, which is too small for the tongue to register texture.

Typically, chocolate makers will add cane sugar at this stage of the process, to grind it with the cacao, but our 100% cacao has no additives besides certain superfoods for some of our enhanced cacao blends.

Chocolate candy makers also often add dairy in this stage, but our process is entirely vegan, because dairy actually inhibits some of the beneficial health effects of cacao.

STEP 4: CONCHING

The fully ground liquid cacao goes through another process called conching, which is a complex process using vigorous agitation, air flow, and heat over time to transform the flavor of the cacao.

With 100% cacao this is particularly important, as it helps volatilize bitter and astringent compounds that are by products of the fermentation process, like acetic acid.

While these compounds are present in cacao nibs, only a small percentage of them reach the tongue when ingested; however when the same cacao nibs are finely ground into smooth 100% cacao, the exponentially higher surface area means that these compounds overwhelm the tasting experience if not removed through proper conching.

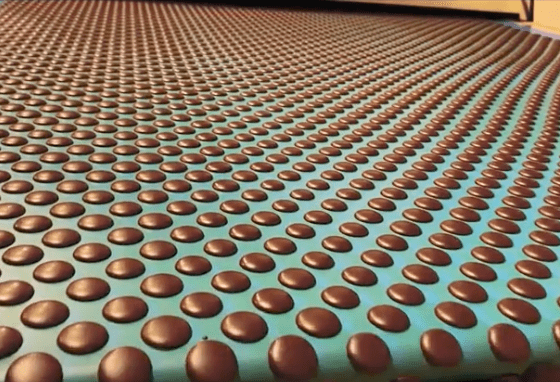

STEP 5: TEMPERING & DEPOSITING

The finished cacao needs to be transferred, tempered, deposited, and cooled into cacao discs.

When we transfer the liquid cacao, we use stainless steel brewery piping. We never pour liquid cacao into plastic buckets or bags, as is common practice in chocolate making.

We also avoid soy lecithin, which is an unnecessary additive added to most industrial cacao to make it flow smoother through pipes and machines.

We make small batches that are freshly shipped to you, rather than deliberately aging the chocolate for flavor or accidentally doing so by distributing through long supply chains.

Prior to depositing our cacao discs, we use a continuous tempering process that through precise control of temperature, seeds the liquid cacao with the crystals we want in our finished product, for best melt resistance and appearance.

Rapid cooling after we deposit the discs forces the liquid cacao to solidify in a crystalline structure based on the crystal seed we’ve selected, rather than cooling more slowly and creating an unorganized mix of crystal, which causes the finished chocolate to appear drab and soft.

Since it is quite rare for chocolate makers anywhere to temper pure 100% cacao, we had our tempering machine custom built with upgraded components to handle thicker, unadulterated chocolate.

Once the chocolate discs are deposited and cooled, we package them and send them to our cacao lovers immediately.

The chocolate discs are a novel innovation that make preparing cacao for ritual as easy as possible.

They are easy to melt and they make it easy to measure out a dose, compared to needing to get out a cutting board, knife, and scale to break apart a big chunk of chocolate before preparing your cacao drink.

Ultimately this entire process is a transformation of a single ingredient, without anything added (besides the highest quality superfoods for our enhanced cacaos) or anything extracted as is done for cocoa powder.

We strive for 100% cacao that is actually quite enjoyable by using selection of the best ingredients and the art of process to achieve superb texture and flavor.

And we take care in every step, avoiding shortcuts such as microwaving our cacao to melt it, something commonly practiced by chocolatiers making truffles and confections.

To us, making ceremonial cacao is a slow food process, and we know that the care taken in every step of the transformation from bean to disc impacts the quality of the healing work that can be done with the cacao.